Controller

airleader Easy

- The big easy

- The inexpensive entry-level

- Full range of functions

- Max. 4 compressors

airleader MASTER 4

- The benchmark

- 10 "touchscreen operation

- Powerful web visualization

- Max. 16 compressors

airleader CN light

-

The large standard

- 17"-touchscreen industrial PC

- Onboard visualization

- Lots of installation space

- Max. 16 compressors

airleader CN Compressor Network

- The gold standard

- 17"-touchscreen industrial PC

- On-board visualization

- Including alarm and service management

- Max. 32 compressors

- Max. 96 digital inputs

- Max. 68 analog inputs

Special functions

FU-Control

(from firmware version 3.0049)

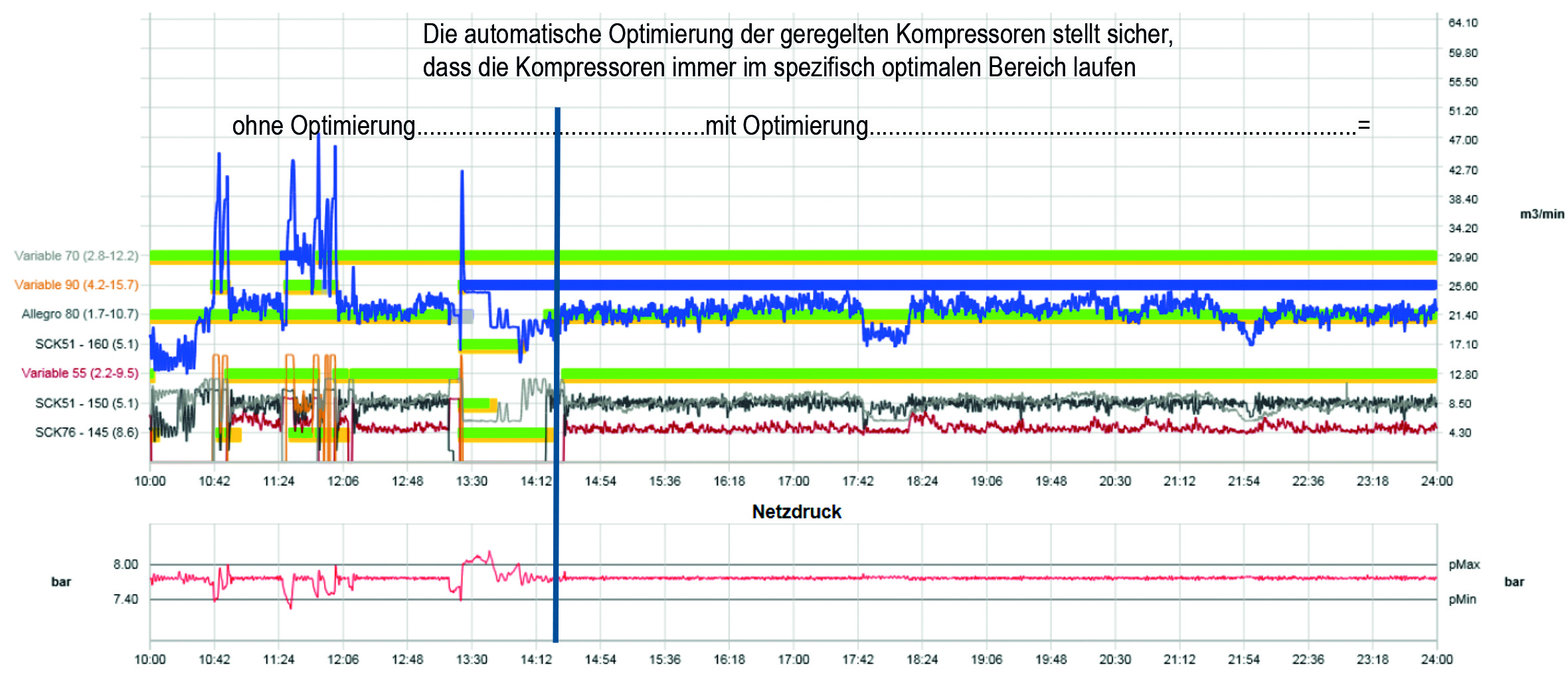

With FU-Control it is now possible to take an active influence to the speed of several speed-controlled compressors from all manufacturers (!)

If several FU compressors are used at the same time, a new algorithm monitors every 5 seconds whether the Compressors run in the "green" range (factory-set to 20 - 80% of the control range, but can be changed).

If not, the pressure setting (ACTUAL pressure on the AO of the connection module) is changed dynamically in order to influence the speed of the compressors accordingly that they run in the optimal speed range as possible. This means that all compressors can be operated safely without interfering with the internal compressor controller or frequency converter!

And this is how optimization works:

This is not yet possible with the previous controllers. The compressors are requested "on load" and adjust to their set pressure. This often leads to the situation that one compressor runs at full throttle and the other at minimum. Both are very inefficient driving styles. This could be partly solved with a fixed pressure offset, but life shows, that it is a dynamic process which cannot adequately react with fixed offsets.

FIX-speed if possible:

Usually the Airleader prefers the frequency converter systems which is usually desired, but usually not particularly energy efficient. Unregulated compressors have fewer internal losses and should be used as soon as possible. This is what this function does when it is activated. As soon as an existing FIX-Speed compressor fits into the control range of the FU compressor (s), the 2nd, 3rd or 4th FU does not come, but a suitable FIX-Speed compressor.

With the new "FU Control" function, a lot more Energy can be saved

Serial no .: 2403-xxxxxx:

- Firmware update is sufficient

Older MASTER modules:

- Simple 1: 1 exchange

- Same dimensions and connectors,

- refunds for newer existing controllers possible

On the basis of new hardware and the newly installed firmware, further improvements have been made.

Control pressure averaging

Faster reaction to pressure fluctuations in widely branched networks. This reduces "fear surcharges" and saves energy.

This means that the control pressure can be defined as the average from pressures at 3 different locations. Pressure sinks often arise far away from the compressor station because heavy consumers switch on. However, the pressure in the compressor station is OK due to differential pressures, as a result of too weakly dimensioned pipework. Machine malfunctions in the pressure sink are the result.

The correct solution would of course be the adaption of the network dimensioning to the actual flow with an additional reserve. However, this is often not possible.

The control pressure averaging can provide a limited remedy for this problem:

From any number of pressure sensors (max. 64), in addition to the reference pressure sensor directly connected on the controller, 2 can be defined as control pressure sensors. The control pressure is then averaged from these 3 pressures. If the pressure on a sensor drops, the control pressure drops accordingly and the control reacts earlier.

If an adjustable pressure difference is exceeded, the corresponding sensors are hidden. This prevents "impossible" pressure values in the event of failure or blockage of a sensor and corresponding incorrect switching.

The entire compressed air generation system works more sensitively and the pressure can be reduced accordingly, since every tenth of a bar saves approx. 1% energy!

WF Steuerungstechnik GmbH

Zeppelinstraße 7-9

75446 Wiernsheim

| Telefon | +49 (0) 7044 911 100 |

| Fax | +49 (0) 7044 5717 |

| info@airleader.de |